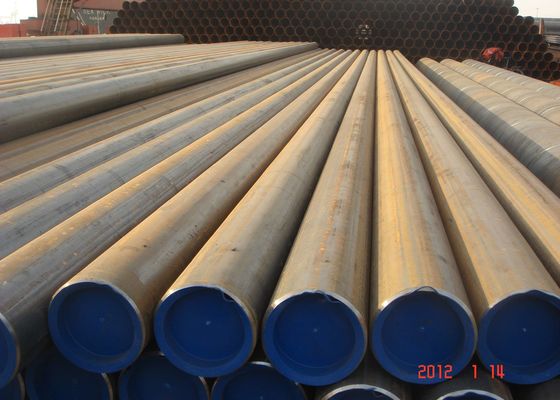

EN10210 EN10219 S275 S355JRH ERW Carbon Steel Tubing

Huayang Steel is considered as the prominent manufacturer, supplier, stockiest and exporter of the wide ranges of Carbon Steel ERW Pipe in the global market. The pipes are available in different specifications, standards, grades, and dimensions. The same is provided in cut-made specifications as per the demand and expectations of the clients. We are considered as the trustworthy manufacturers of the pipes that are accepted by a large number of buyers. They are using these pipes in various applications in both the use of household and for commercial purposes. Many industries are using these pipes such as pharmaceuticals, petrochemicals, power generation, and many others.

The specified pipes are manufactured by an electron beam welding. And it contains high-speed kinetic energy which is helped in welding the appropriate pipes that are mostly used for high-temperature contents. The technique is used for welding dissimilar steel and has a high power density. These pipes are used to complete the piping system in the industries especially in the oil and gas refinery. The pipes are usually beneficial for working or transferring the liquids from one place to another.

The nomenclature ERW refers to a specific type of welding process that involves both spot and seam welding. Seam welding is commonly used during the manufacturing of round, square and rectangular steel tubing. The steel strip is unwound from coils and side-trimmed to control width and condition the edges for welding. The strip then passes through a series of contoured rollers which cold-form the material into a circular (square or rectangular) shape. The edges are forced together under pressure as a butt joint and then welded by heating the material to temperatures above 2000° F. The flash weld that has formed is now removed from the outside diameter of the tube. Once the weld has been tested the tube then passes through a series of sizing rolls to attain its precise finished size, after which the tube is then straightened and cut to length.

Out Diameter:114.3mm - 812.8mm (4"-32")

Length:3M-18M

Wall Thk:4mm-22mm

Certificate:ISO 9001, ISO 14001, OHSAS 18001, API 5L PSL1&PSL2, CE (CPR & PED), GOST Certificates

EFW:Electric Fusion Welded Pipe

Usage:Used for construction field, low pressure liquid transportation, in various engineering purposes, fencing, scaffolding etc.

Steel Grade:

EN10210/EN10219: S275, S275JR, S355JRH, S355J2H

Surface:Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement

Tests:Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test.

MTC:EN 10204/3.1B, EN 10204/3.2 (with Third Party Inspection

Size & Thickness:

| Dimension |

Wall Thickness |

| |

mm |

3.99 |

4.78 |

6.02 |

6.35 |

7.11 |

7.92 |

8.74 |

9.53 |

10.31 |

11.13 |

11.91 |

12.70 |

14.27 |

15.88 |

17.48 |

19.05 |

20.62 |

| inch |

|

0.157 |

0.188 |

0.237 |

0.250 |

0.280 |

0.312 |

0.344 |

0.375 |

0.406 |

0.438 |

0.469 |

0.500 |

0.562 |

0.625 |

0.688 |

0.750 |

0.812 |

| 4 |

114.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 6 |

168.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 8 |

219.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 10 |

273.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 12 |

323.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 14 |

355.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 16 |

406.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 18 |

457.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 20 |

508 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 22 |

558.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 24 |

609.6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 26 |

660.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 28 |

711.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 32 |

812.8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!