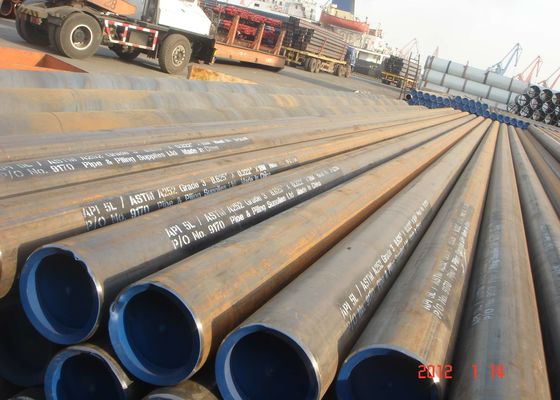

ASTM 53 EN10217 DIN 2458 EN10219 S355J2H CS ERW Pipe

Out Diameter :114.3mm - 812.8mm ( 4 "- 32 " ) EN10210 / EN10219 S355J2H ERW Carbon Steel Pipe

Is there any difference between HFW steel tube and ERW steel tube?

The main difference between ERW and HFW is the principle.

As the name suggests, resistance welding is a method in which the welding parts are combined and applied pressure through the electrode, and the resistance heat generated by the current passing through the contact surface of the joint and the adjacent area is used for welding.High-frequency welding: when high-frequency current passes through the metal conductor, it will produce two peculiar effects: skin effect and proximity effect. High-frequency welding is to use these two effects to carry out the welding of steel pipe. These two effects are the basis of realizing high-frequency metal welding.

High frequency welding is to use the skin effect to make high frequency current energy concentrated on the surface of the workpiece;The proximity effect is used to control the location and range of the high frequency current flow path.The speed of the current is very fast, it can be in a very short time to the adjacent steel plate edge heating, melting, and through extrusion to achieve the butt has its own advantages, but also has its own disadvantages.Want to be analysed according to specific case commonly specific choice.

Standard: EN10219,EN10217

Steel Grade:EN10210/EN10219: S275, S275JR, S355JRH, S355J2H

ERW :Electric Resistance Welded pipe

Out Diameter:114.3mm - 812.8mm (4"-32")

Length:3M-18M

Wall Thk:4mm-22mm

Certificate:ISO 9001, ISO 14001, OHSAS 18001, API 5L PSL1&PSL2, CE (CPR & PED), GOST Certificates

Usage:Used for construction field, low pressure liquid transportation, in various engineering purposes, fencing, scaffolding etc.

Surface:Fusion bond Epoxy coating, Coal Tar Epoxy, 3PE, Vanish Coating, Bitumen Coating, Black Oil coating as per customer’s requirement

Tests:Chemical Component Analysis, Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation), Technical Properties (Flattening Test, Bending Test, Blow Test, Impact Test), Exterior Size Inspection, Hydrostatic Test.

MTC:EN 10204/3.1B, EN 10204/3.2 (with Third Party Inspection

S355J2H Pipe Specification

| Standard No |

EN 10210 |

| Standard Name |

Hot Finished Structural

Hollow Sections of Non-alloy

and Fine Grain Steels |

| Grade |

S235JRH,S275JOH,S275J2H,S355JOH,S355J2H,S355K2H,S275NH,

S275NLH,S355NH,S355NLH,S420NH,S420NLH,S46INH,S460NLH |

| Dimension Range |

21.3-1219mm |

Carbon Steel Pipes Chemical Composition

| Grade |

C |

Si |

Mn |

P |

S |

| S355J2H (1.0576) |

max 0.22 |

max 0.55 |

max 1.6 |

max 0.03 |

max 0.03 |

S355J2H Heat Treatment / Hot Forming

| Hot Forming |

Heat Treatment |

| Temperature°C |

Cooling Type |

Normalizing 1″ |

Stress relieving anneal 2″ |

Cooling Type |

| 700-750 |

Air |

850-950°C |

580-630°C |

Air |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!